Finishing Machines & Consumables

These machines and consumables are ideal for finishing a range of products in the signage industry.The HEMTEK ST is designed for use in a wide range of applications and is particularly intuitive to use. Once the machine is mounted, you can start welding immediately.

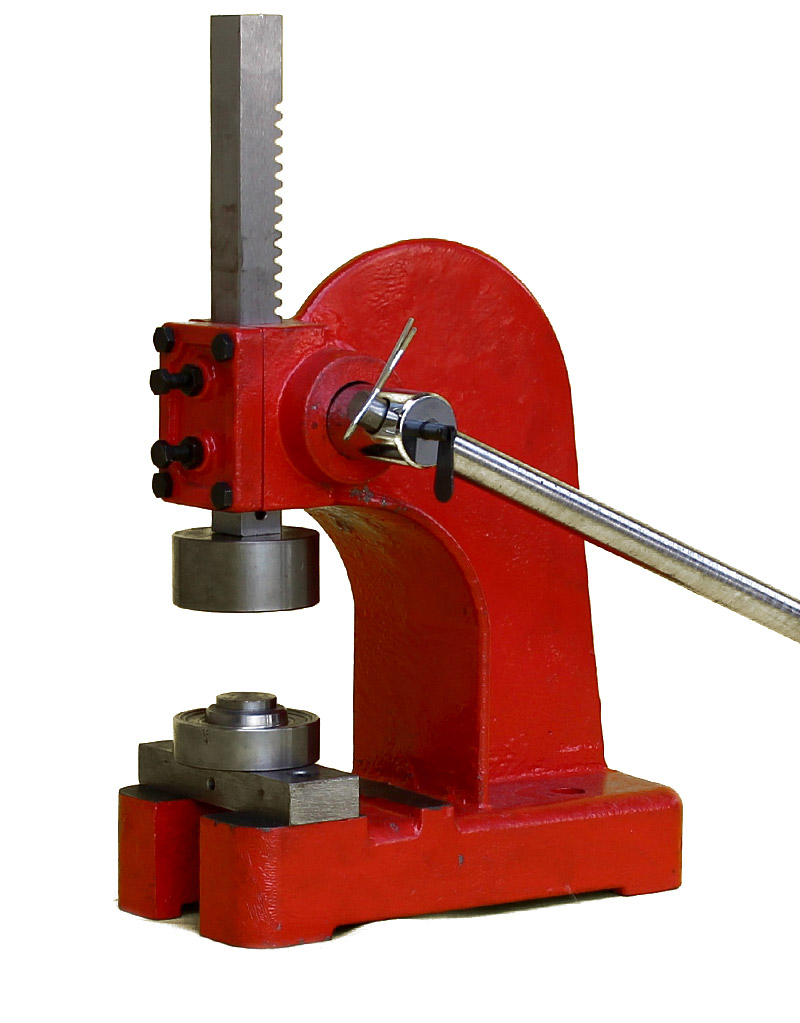

ML1 Eyelet Machine

Manual Lever Machine. Robust manual press with the ability to set hard wearing stainless steel eyelets. One die set will pre cut the hole and set the eyelet and washer.

MP10 Eyelet Machine

Manual Pneumatic Machine. Designed to increase the productivity of low volume settings, after manually placing eyelet and washer, the powerful pneumatic ram cuts the hole and sets eyelets in one motion. The light-weight design allows for portable operation.

AP40 Eyelet Machine

Automatic Pneumatic Machine. Powerful, fast and safe setting action, you can effortless sets eyelets with washers in one operation The foot press keeps your hands free, you can set up to 38 eyelet & washers per minute!

Eyelets (#2 & #4)

Our Stainless steel eyelets are sheet eyelets, not self piercing. This means you are not relying on the thin eyelet to cut through your material, instead our robust die sets precut the hole, and our eyelet and toothed washer lock on tight.

The most popular sizes for this industry are the #2 (SP4 equivalent) and #4 (SP7 equivalent).

Keder 7.5mm

Keder is used to attach a billboards or banners to a structure using an aluminium track system. The flap of the keder can be welded to PVC or sewn. 7.5mm is the most common for this application.

40mm Webbing

Our PVC coated polyester scrim webbing is ideal for reinforcing hems on mesh and banners. This can be welded or sewn onto PVC, and sewn onto polyester. Available in 50m coils.

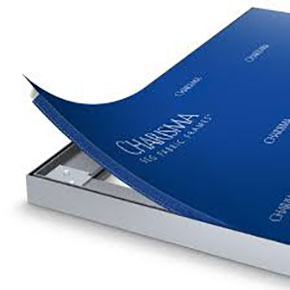

Silicon Edge

Silicon edge is stitched onto stretch display fabric, used in Aluminium display stands. This system is proving especially popular for expos and retail displays as the end user can easily set up without a professional installer. Available in the following profiles

- 14mm x 3mm

- 20mm x 3mm

- 6mm x 4mm