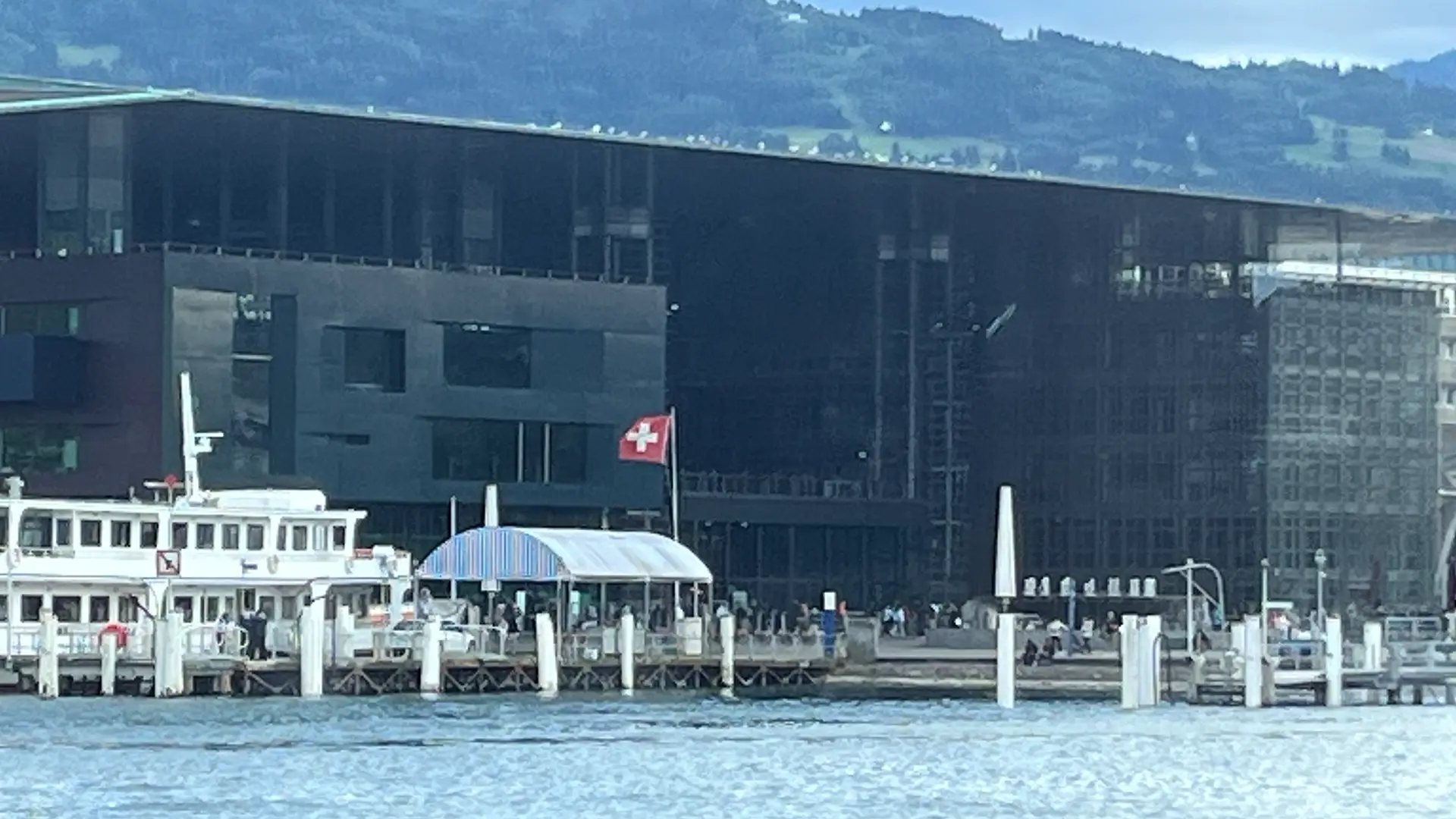

This year Leister hosted its first global distributor conference in Lucerne, Switzerland since 2019. Leister is also celebrating its 75th year in business.

Representatives from 70 countries/regions attended the conference. The first day was a great opportunity to hear from a few new people now leading Leister into the future. Two years ago, Leister set up Leister International with the sole purpose of supporting global distributors.

Leister has been investing in more experts to be available globally to assist distributors with all their customers’ requirements. Examples include helping to design process heat systems for a full array of manufacturing requirements and geotechnical applications and projects.

The biggest message from Mrs. Leister, the Chairperson of the Board, was her commitment that the company will continue to invest and innovate to the highest standards and be the market leader.

The distributors also spent a day at Leister’s Production Facility where workshops were held by all the different Product Business Lines. We were given a glimpse into what innovations and product developments may be possible in the future. The industries involved in all plastic fabrication are also ever-changing. Leister is committed to being a world leader in terms of their tools and accessories to meet the market’s needs.

It was amazing to see the innovations they are working on at present.

John Carr (middle) receiving a certificate acknowledging Carr Group’s 65 years as a Leister distributor. Pictured with Andy Means, Chief Operating Officer for Leister Technologies (left) and Martin Sailer, General Manager, Leister International (right).

The conference was capped off with distributors who have had more than 25 years of collaboration with Leister being recognised.

John Carr received a certificate honouring the 65 years that Leister has been working with Carr as a distributor, an amazing achievement and recognition for our company.

The Carr Group is the third longest-serving distributor for Leister, just behind Plastral Australia with 67 years and Welwyn England with 70 years.

Even though New Zealand is a smaller market at the bottom of the world, Leister was very interested in what we are doing in the country and interested in our ideas for future tool/accessory development.

One of the main focuses for Leister is creating more energy-efficient products, given that the cost of electricity continues to rise globally and that this is a very real cost to business. Businesses are also looking to move away from fossil fuels, such as natural gas and coal.

An example we witnessed was in South America where a company used handheld hot air guns from Dewalt and Makita for their production. They were replacing each tool eight times per year, on average, and throwing them in the bin.

These tools also draw the maximum amount of power constantly during use. The distributor for Leister did a simple exercise with an amp meter to compare the other brands’ power use with that of Leister’s Solano AT.

When the Solano is used in Eco mode, it uses less power when in the rest position and only draws full power when it is needed.

Doing the power calculations and considering the longer life of the Solano AT, allowed the company in South America to save more money overall than just buying the cheapest tool on the market, which they were regularly throwing away.

We encourage you, our customers, to visit the Leister website https://www.leister.com and explore the Products, Solutions and Services tabs to find interesting articles and information produced to support the different industries you work in.

And if you haven’t accessed it already, remember the MyLeister App is also great to have on your phone. Along with allowing you to interface with any tools you have which are equipped with the Leister Quality System (LQS), it contains a range of information, including standard welding recipes for different machines and the types of materials being welded. You can also register all your tools under your app to keep a clear record, especially valuable if you have multiple tools.